IISc finds safer way to mass production recombinant proteins like insulin | India News – Times of India

[ad_1]

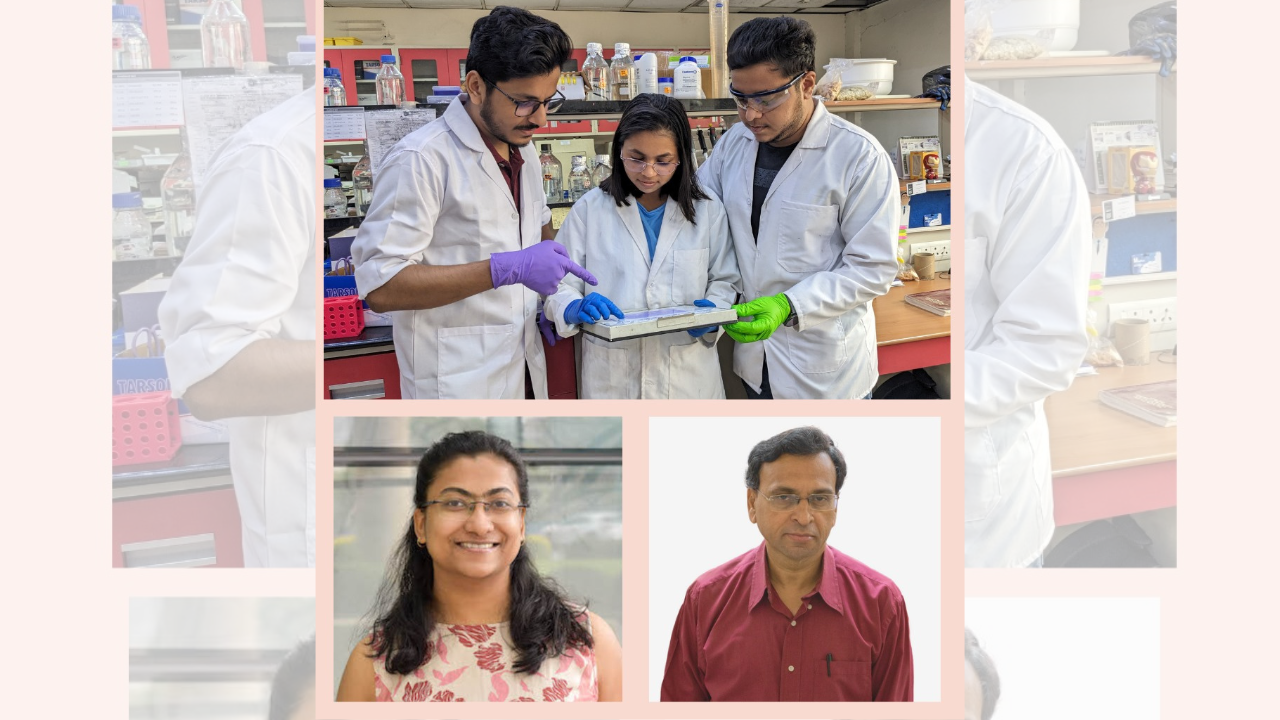

BENGALURU: Researchers at the Indian Institute of Science (IISc) have developed a novel and safer method to mass produce recombinant proteins such as vaccine antigens, insulin and monoclonal antibodies using the common food additive mono-sodium glutamate (MSG) instead of the hazardous methanol.

Researchers hope that this novel and indigenous expression system can be used in biotech industries to mass-produce valuable proteins including milk and egg proteins, baby food supplements and nutraceuticals, apart from therapeutic molecules.

An Indian patent has been granted for the expression system and a US patent has been filed. The team is also looking for industry collaborators to scale up the system for mass production.

Hazardous conventional method

The conventional method to manufacture recombinant proteins involves using the yeast Pichia pastoris (now called Komagataella phaffii) activated by methanol. However, methanol is highly flammable and hazardous, requiring stringent safety precautions.

To solve this problem, Trishna Dey, a former PhD student at IISC’s department of biochemistry (BC), started looking for alternatives. “After an extensive search, the team found that MSG, a USFDA approved food additive, can activate a different promoter in the yeast genome that codes for an enzyme called phosphoenolpyruvate carboxykinase (PEPCK),” IISc said.

It added that activating this promoter with MSG led to protein production similar to methanol activation of the AOX promoter.

Overcoming challenges

Optimising the cell culture medium for this new and untested process was challenging, says Neetu Rajak, the first author and PhD student at BC, adding that for a long time, the yeast cells grew poorly in shake flasks and produced very little recombinant protein.

“…There was a time when we almost gave up because we thought it was not going to work,” said Prof PN Rangarajan, a corresponding author of the study published in Microbial Cell Factories.

The group eventually figured out that using MSG alone was not enough. Vedanth Bellad and Yash Sharma, project assistants at BC and co-authors, explain that they tried supplementing the culture with various other compounds, until one finally did the trick: Ethanol.

Adding ethanol helped the cells grow faster, which increased the biomass and the amount of recombinant protein produced. Ethanol is also safer for yeast cells compared to methanol, as it does not produce toxic byproducts when broken down.

“To test their process, the team tried producing the SARS-CoV-2 receptor binding domain – a widely-used vaccine antigen that has been successfully expressed in yeast and mammalian cells. They found that their new expression system produced twice the amount of antigen compared to the methanol-induced process,” IISc said.

Researchers hope that this novel and indigenous expression system can be used in biotech industries to mass-produce valuable proteins including milk and egg proteins, baby food supplements and nutraceuticals, apart from therapeutic molecules.

An Indian patent has been granted for the expression system and a US patent has been filed. The team is also looking for industry collaborators to scale up the system for mass production.

Hazardous conventional method

The conventional method to manufacture recombinant proteins involves using the yeast Pichia pastoris (now called Komagataella phaffii) activated by methanol. However, methanol is highly flammable and hazardous, requiring stringent safety precautions.

To solve this problem, Trishna Dey, a former PhD student at IISC’s department of biochemistry (BC), started looking for alternatives. “After an extensive search, the team found that MSG, a USFDA approved food additive, can activate a different promoter in the yeast genome that codes for an enzyme called phosphoenolpyruvate carboxykinase (PEPCK),” IISc said.

It added that activating this promoter with MSG led to protein production similar to methanol activation of the AOX promoter.

Overcoming challenges

Optimising the cell culture medium for this new and untested process was challenging, says Neetu Rajak, the first author and PhD student at BC, adding that for a long time, the yeast cells grew poorly in shake flasks and produced very little recombinant protein.

“…There was a time when we almost gave up because we thought it was not going to work,” said Prof PN Rangarajan, a corresponding author of the study published in Microbial Cell Factories.

The group eventually figured out that using MSG alone was not enough. Vedanth Bellad and Yash Sharma, project assistants at BC and co-authors, explain that they tried supplementing the culture with various other compounds, until one finally did the trick: Ethanol.

Adding ethanol helped the cells grow faster, which increased the biomass and the amount of recombinant protein produced. Ethanol is also safer for yeast cells compared to methanol, as it does not produce toxic byproducts when broken down.

“To test their process, the team tried producing the SARS-CoV-2 receptor binding domain – a widely-used vaccine antigen that has been successfully expressed in yeast and mammalian cells. They found that their new expression system produced twice the amount of antigen compared to the methanol-induced process,” IISc said.

[ad_2]

CATEGORIES INDIA